Uncategorised

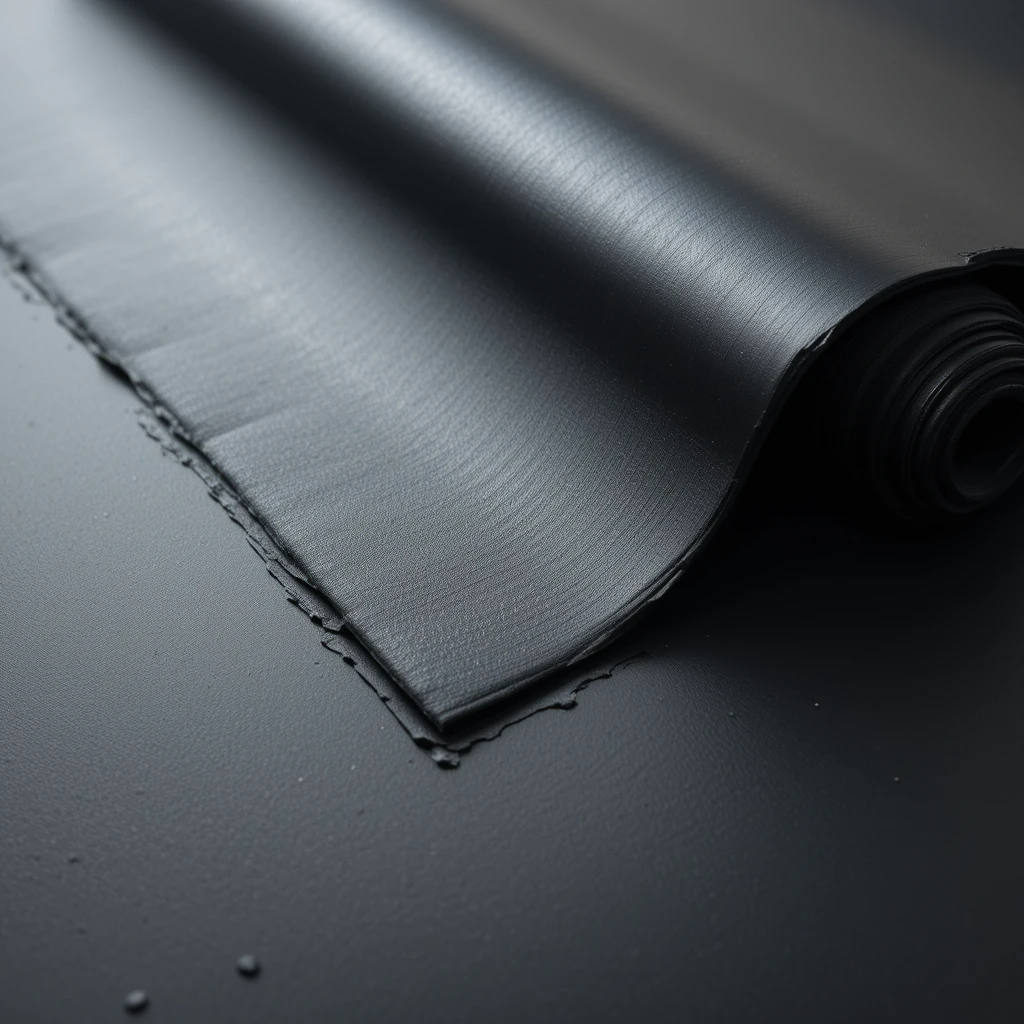

How to Choose the Best Gasket Material: EPDM, Silicone & Food-Grade Options

A Comprehensive Guide to Material Properties, Use Cases, and Buying Tips for UK Buyers

When selecting gaskets for industrial, food production, or household use, choosing the right material is crucial. It can affect durability, safety, performance, and compliance. In 2025, with Google’s SEO criteria evolving, content that demonstrates expertise, trustworthiness, and clear answers is more important than ever.

What to Consider When Choosing Gasket Materials

| Feature | EPDM Rubber | Silicone / Food-Grade |

|---|---|---|

| Temperature Range | Moderate heat resistance (-40°C to ~120°C) | Extreme ranges (-50°C to 200°C+) |

| Chemical Resistance | Good with water, steam; weaker against oils/fuels | Excellent for oils, fats, and food products |

| Regulatory Compliance | Standard industrial applications | Needs FDA or similar food / medical compliance |

Common Uses

- Outdoor sealing, weather stripping → EPDM

- Kitchen equipment, espresso, food processing → Food-grade silicone

- Engine / mechanical equipment (fuel, oil) → Viton or NBR

How to Buy with Confidence

- Look for certifications (FDA, LFGB, etc.)

- Ask for data sheets or test reports

- Check warranty and replacement policies

Conclusion

Choosing the right gasket material—whether EPDM, silicone, or food-grade silicone—depends on your application, safety requirements, and durability expectations. By understanding the strengths of each material, you can make smarter purchasing decisions that save time, reduce maintenance, and ensure compliance.

At CSMade, we specialize in custom-cut gaskets tailored to your exact needs. Whether you need high-performance gaskets for industrial machinery or safe, FDA-approved silicone gaskets for the food industry, we can provide the right solution at a competitive price. Explore our full range today and find the gasket that fits your application perfectly.