Custom gaskets

Applications and benefits of EPDM rubber

Ethylene Propylene Diene Monomer (EPDM) rubber is a highly versatile synthetic elastomer renowned for its exceptional durability and wide range of applications. This thermosetting material exhibits superior resistance to weathering, ozone, UV radiation, and a variety of chemicals, making it an ideal choice for both indoor and outdoor applications. Its unique molecular structure, characterized by a saturated polymer backbone, contributes to its impressive stability and longevity in harsh environments.

Key Uses of EPDM Rubber:

1. Automotive Industry:

EPDM rubber plays a crucial role in the automotive sector, where it is used extensively in the manufacture of seals, hoses, weather stripping, and other components that require resistance to extreme temperatures, fluids, and weathering. Its ability to maintain flexibility and elasticity over a wide temperature range makes it an indispensable material for automotive applications.

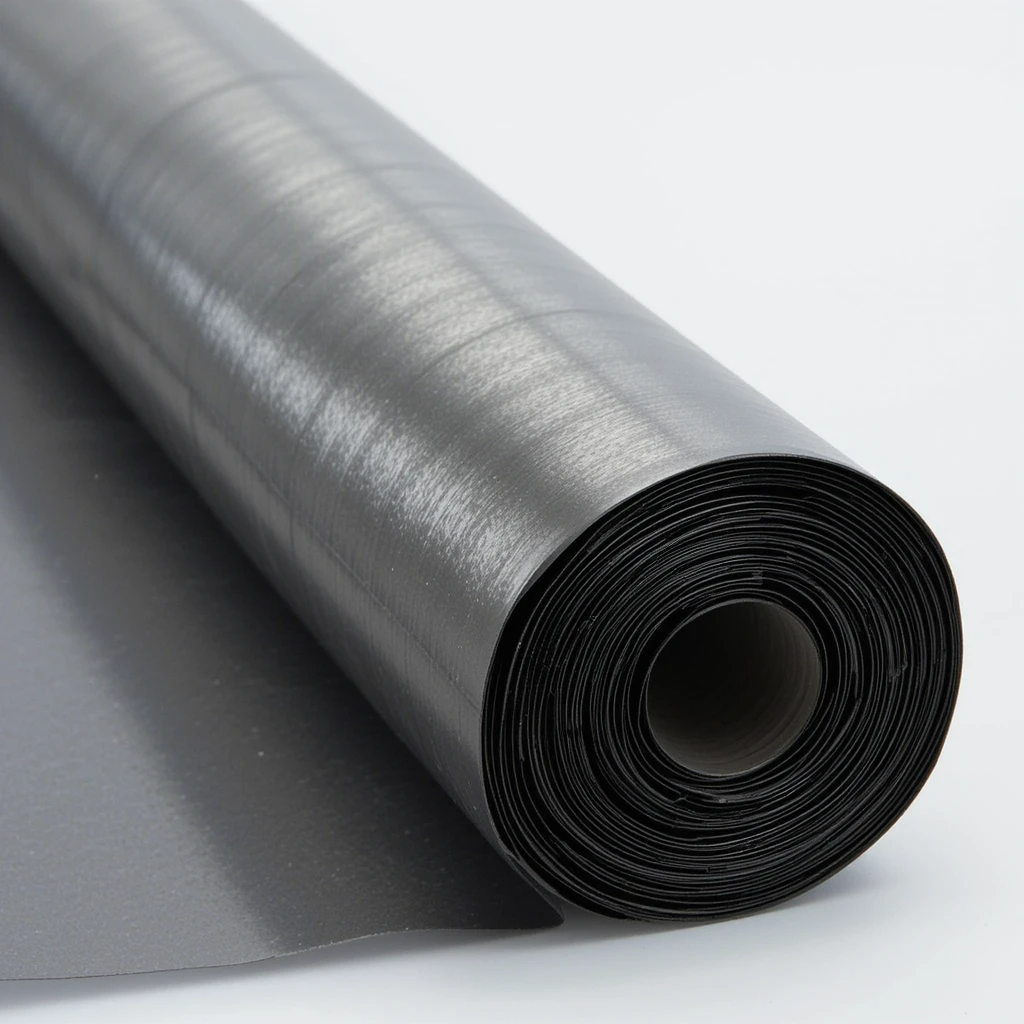

2. Construction Industry:

In the construction industry, EPDM rubber is primarily utilized for roofing membranes, seals, and gaskets. Its exceptional resistance to UV radiation, ozone, and weathering ensures long-term protection against the elements. EPDM roofing systems are known for their durability, low maintenance requirements, and ability to withstand extreme temperature fluctuations.

3. HVAC Systems:

EPDM rubber is widely used in heating, ventilation, and air conditioning (HVAC) systems for seals, gaskets, and hoses. Its resistance to refrigerants, coolants, and temperature variations ensures reliable performance and prevents leaks.

4. Electrical Insulation:

EPDM rubber’s excellent dielectric properties make it suitable for electrical insulation applications, such as cable insulation, connectors, and insulators. Its ability to withstand high voltages and resist degradation in harsh environments ensures safe and reliable electrical performance.

5. Industrial Applications:

EPDM rubber finds numerous applications in various industrial settings, including the manufacturing of seals, gaskets, hoses, conveyor belts, and other components that require resistance to chemicals, abrasion, and extreme temperatures.

6. Waterproofing:

Due to its impermeability and resistance to water damage, EPDM is employed in a variety of waterproofing applications, such as pond liners, reservoir linings, and other containment systems.

Benefits of EPDM Rubber:

1. Exceptional Weather Resistance:

EPDM rubber exhibits superior resistance to ozone, UV radiation, and weathering, making it ideal for outdoor applications where exposure to the elements is a concern.

2. Wide Temperature Range:

EPDM rubber maintains its flexibility and elasticity over a wide temperature range, typically from -50°C to 150°C, making it suitable for both hot and cold environments.

3. Chemical Resistance:

EPDM rubber demonstrates excellent resistance to a variety of chemicals, including acids, alkalis, and solvents, making it suitable for use in harsh chemical environments.

4. Durability and Longevity:

EPDM rubber is a highly durable material that can withstand years of use without significant degradation. Its long lifespan reduces the need for frequent replacements, resulting in cost savings over time.

5. Low Maintenance:

EPDM rubber requires minimal maintenance, further reducing long-term costs.

6. Versatility:

EPDM rubber can be easily molded, extruded, and calendered into a variety of shapes and sizes, making it a versatile material for a wide range of applications.

7. Cost-Effectiveness:

Compared to other high-performance elastomers, EPDM rubber offers a cost-effective solution for applications requiring exceptional durability and resistance to harsh environments.

8. Electrical Properties:

EPDM rubber possesses good dielectric properties, making it suitable for electrical insulation applications.

9. Environmental Resistance:

EPDM is resistant to many environmental factors, including steam, water, and polar substances.

Conclusion

In conclusion, EPDM rubber is a highly versatile and durable material that offers a wide range of benefits for various applications. Its exceptional resistance to weathering, chemicals, and extreme temperatures, combined with its low maintenance requirements and cost-effectiveness, makes it an ideal choice for demanding environments. From automotive components to roofing membranes and electrical insulation, EPDM rubber continues to play a crucial role in numerous industries, ensuring long-lasting performance and reliability.