When it comes to brewing the perfect cup of coffee, every detail matters — and that includes the silicone gasket for your Moka pot. A high-quality gasket ensures a tight seal between the upper and lower chambers of your coffee maker, preventing steam leaks and helping you extract full flavour from your coffee grounds. ☕ […]

Learn what the IMPA code means for rubber gaskets used in marine applications. Find EPDM, nitrile, neoprene, and silicone gaskets — custom-made or IMPA standard. Fast delivery across the UK. Rubber Gasket IMPA Code – Understanding Marine Sealing Standards The IMPA Code (International Marine Purchasing Association Code) is a universal classification system used by the […]

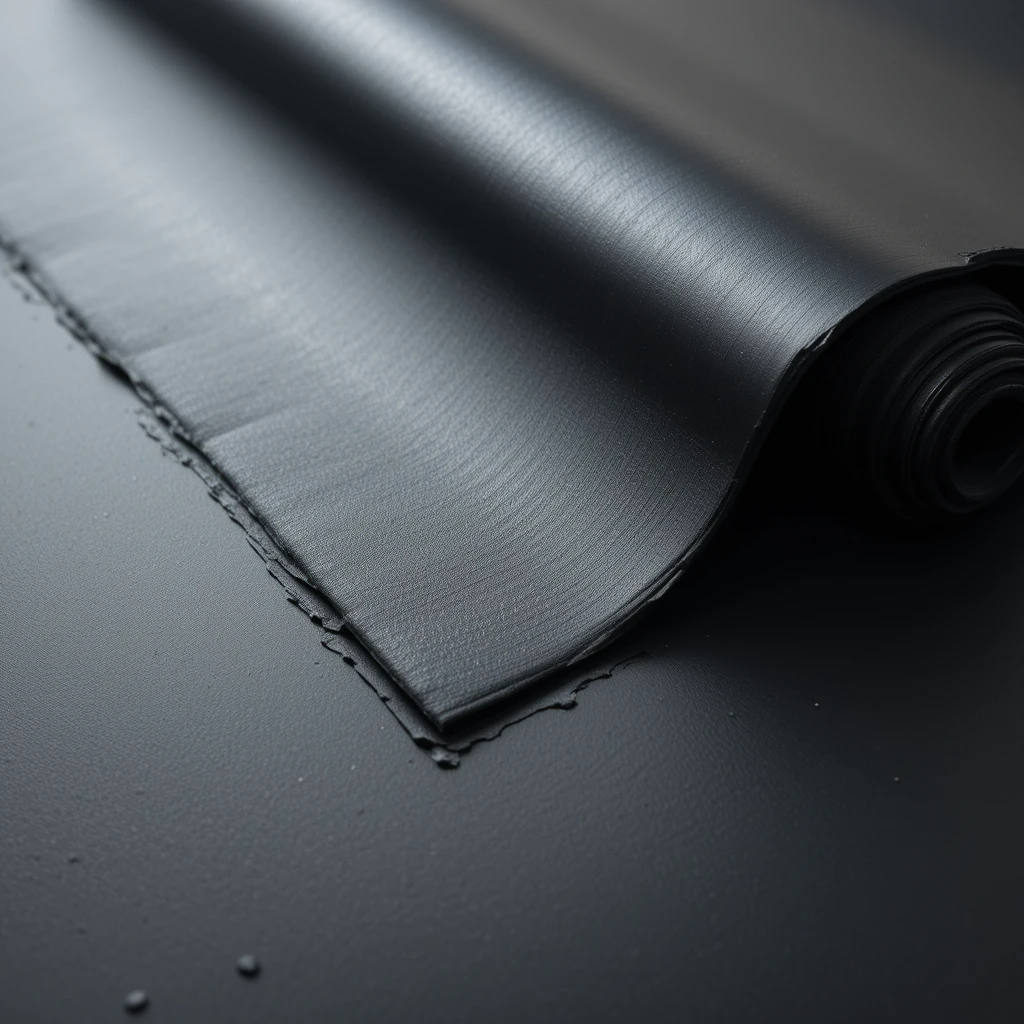

When it comes to reliable and long-lasting sealing performance, EPDM gasket material is one of the most popular and versatile choices available. Known for its excellent resistance to weather, ozone, and a wide range of chemicals, EPDM rubber is used across multiple industries — from automotive and HVAC to construction, electrical, and marine applications. At […]

When it comes to industries where safety and hygiene are critical, food grade silicone gaskets are one of the most reliable sealing solutions available. Designed to withstand extreme conditions while remaining safe for contact with food and beverages, these gaskets are widely used across food processing, beverage production, pharmaceuticals, and catering equipment. Why Choose Food […]

What Is Custom Gasket Manufacturing? Custom gasket manufacturing is the process of designing and producing gaskets tailored to specific applications, machinery, or environmental conditions. Unlike standard off-the-shelf gaskets, custom gaskets are engineered to match exact dimensions, materials, and performance requirements — ensuring a perfect seal and long-term reliability. Why Choose Custom Gaskets? Every industry has […]

In today’s fast-moving industries, precision and reliability are everything. Gaskets may seem like small components, but they play a critical role in preventing leaks, ensuring safety, and maintaining performance across countless applications. From automotive and construction to food processing and medical equipment, custom gaskets are the invisible heroes keeping systems running smoothly. Why Choose Custom […]

When it comes to the food and beverage industry, selecting the right sealing material is one of the most critical decisions for ensuring safety, hygiene, and efficiency. Gaskets and seals play a vital role in preventing leaks, contamination, and costly downtime. With strict regulations and demanding operating conditions, choosing the best gasket material for food […]

A Comprehensive Guide to Material Properties, Use Cases, and Buying Tips for UK Buyers When selecting gaskets for industrial, food production, or household use, choosing the right material is crucial. It can affect durability, safety, performance, and compliance. In 2025, with Google’s SEO criteria evolving, content that demonstrates expertise, trustworthiness, and clear answers is more […]

In the food and beverage industry, safety and hygiene are top priorities. Equipment must operate under strict standards to ensure there is no contamination, leakage, or product loss. That’s why the use of high-quality gaskets—especially food grade silicone gaskets—is essential. At CSMade, we provide custom solutions designed to meet the demanding needs of food processing […]

Gaskets play a crucial role in modern industries, ensuring reliable sealing, preventing leaks, and improving safety across countless applications. At CSMade, we specialize in custom cut gaskets UK, offering tailored solutions to meet the diverse needs of industrial sectors. Why Gaskets Are Essential in Industry A gasket’s main function is to create a tight seal […]