Custom gaskets

Custom gaskets and seals

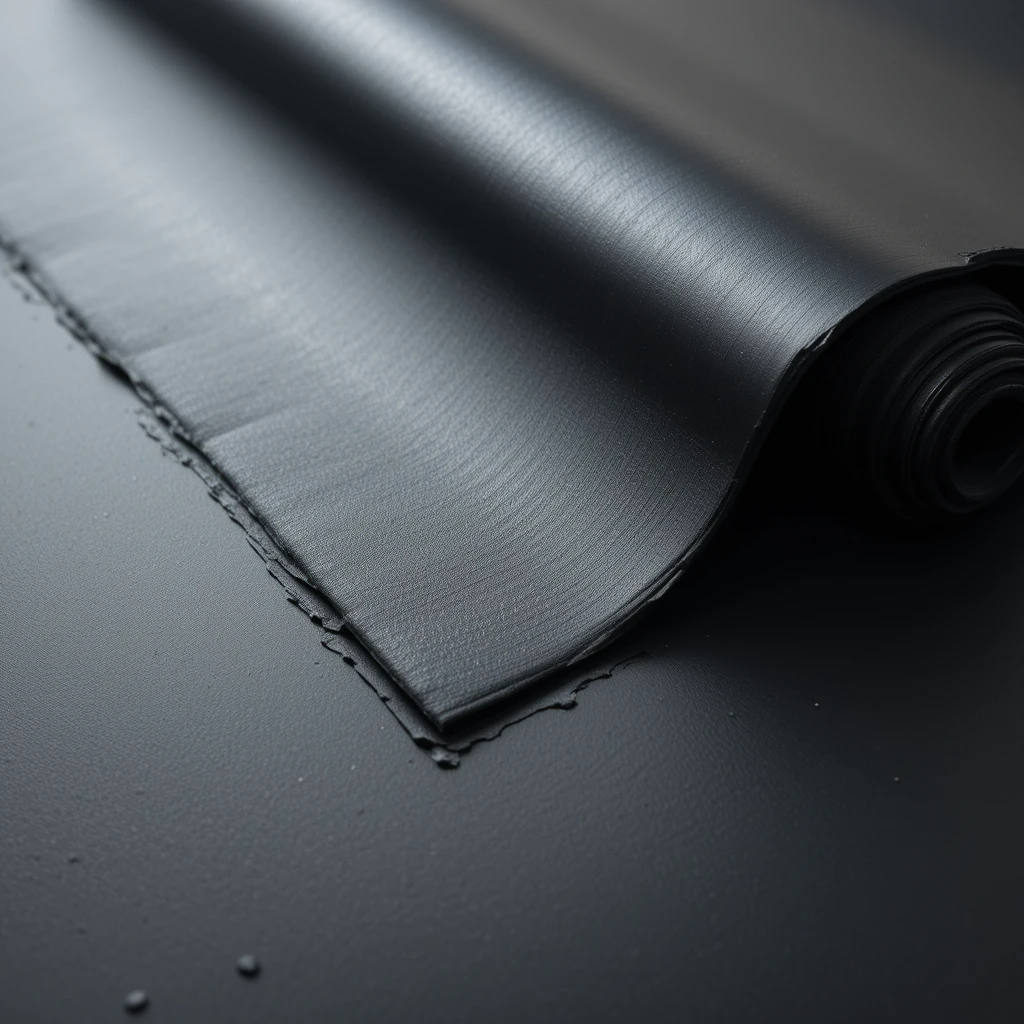

Custom Gaskets and Seals: Precision Solutions for Every Industry

When standard sealing solutions fall short, custom gaskets and seals provide the reliability, performance, and fit your application demands. From aerospace and automotive to food processing and pharmaceuticals, custom gaskets are engineered to meet strict performance requirements under even the most extreme conditions.

What Are Custom Gaskets and Seals?

Custom gaskets and seals are specialized components designed to prevent leaks, contain pressure, and protect sensitive components from environmental exposure. Unlike off-the-shelf products, custom seals are manufactured to your exact specifications, including material type, size, thickness, and resistance properties.

Why Choose Custom Over Standard?

Choosing custom gaskets and seals offers several benefits:

- Perfect Fit: Designed to match your specific equipment, minimizing the risk of leaks and performance issues.

- Material Versatility: Select from a wide range of materials—rubber, silicone, PTFE, graphite, metal, and more—based on chemical compatibility, temperature, and pressure demands.

- Enhanced Durability: Custom-engineered seals can last longer and perform better under harsh conditions.

- Industry Compliance: Meet industry standards such as FDA, RoHS, UL, and ISO, critical for applications in regulated sectors.

Industries We Serve

Our custom gasket and seal solutions are trusted across multiple industries:

- Automotive – Engine seals, exhaust gaskets, and fluid system seals

- Aerospace – High-performance sealing for fuel, hydraulics, and electronics

- Food & Beverage – FDA-grade materials for sanitary sealing solutions

- Pharmaceutical – Cleanroom-compatible seals and gaskets

- Oil & Gas – Extreme temperature and pressure-resistant sealing components

- Electronics – EMI/RFI shielding gaskets and environmental seals

Custom Gasket and Seal Manufacturing Capabilities

Our advanced manufacturing processes ensure precision and consistency:

- Die Cutting

- Waterjet and Laser Cutting

- Compression Molding

- Injection Molding

- CNC Machining

We offer both low-volume prototyping and high-volume production with fast turnaround times.

Choosing the Right Gasket Material

Material selection is critical to the success of any sealing application. Common materials include:

- Nitrile (Buna-N) – Oil and fuel resistance

- EPDM – Weather, ozone, and UV resistance

- Silicone – High-temperature and food-safe

- PTFE (Teflon) – Chemically inert and non-stick

- Viton – High chemical and temperature resistance

Get a Custom Quote Today

Whether you need a one-off prototype or ongoing production runs, we offer competitive pricing and expert engineering support. Contact us today to discuss your project requirements and receive a fast, no-obligation quote.