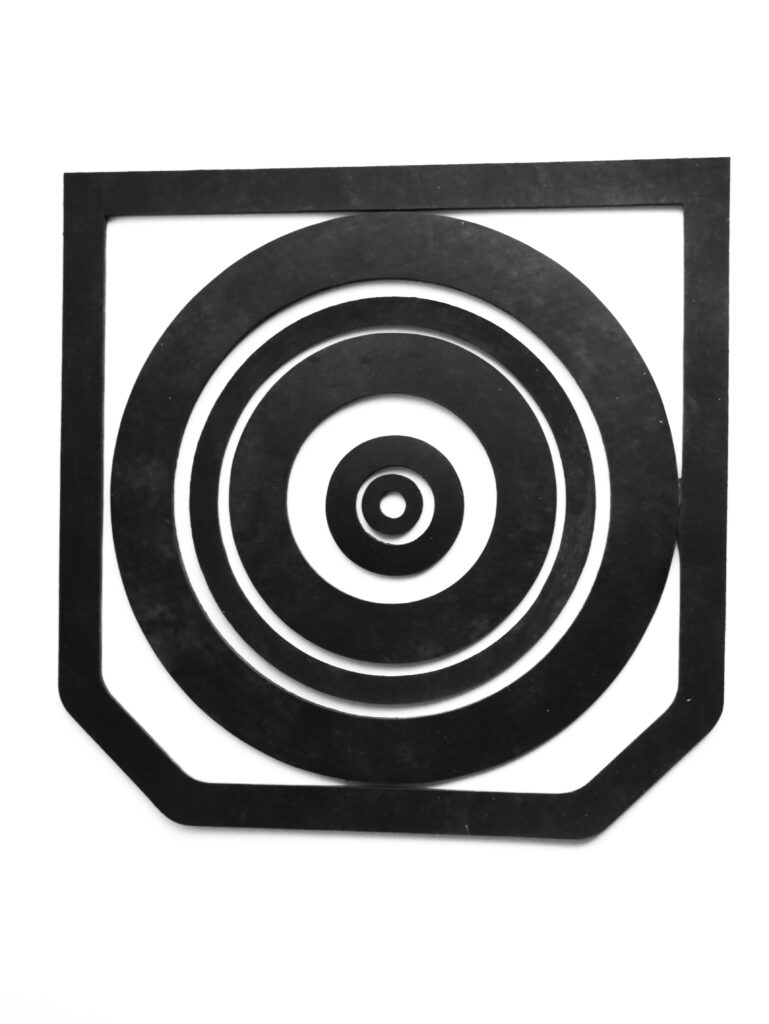

Custom gaskets

Epdm gaskets for steam

Introduction

EPDM (ethylene propylene diene monomer) gaskets are a commonly used sealing solution in various industrial applications due to their excellent resistance to weathering, ozone, UV radiation, and chemicals. However, when considering the use of EPDM gaskets in steam applications, it is crucial to understand their limitations and suitability.

Temperature range

EPDM is generally not recommended for high-temperature steam applications. While standard EPDM can withstand temperatures up to approximately 120-150°C (250-300°F) in dry heat, the presence of steam significantly reduces its service life and sealing performance. Steam is a highly aggressive medium, and at elevated temperatures, it can cause EPDM to degrade, soften, swell, and lose its mechanical properties, leading to premature failure and potential leakage.

Degradation in steam

The primary mechanism of degradation in steam is hydrolysis, where water molecules break down the polymer chains of the EPDM. This process is accelerated at higher temperatures and pressures. Additionally, the high kinetic energy of steam molecules can cause erosion and abrasion of the gasket surface, further compromising its integrity.

Application

For applications involving steam, especially at high temperatures and pressures, alternative gasket materials are generally more suitable. Materials such as expanded graphite, PTFE (polytetrafluoroethylene), or certain types of compressed non-asbestos fiber (CNAF) gaskets are specifically designed to withstand the harsh conditions of steam environments. These materials exhibit superior thermal stability, chemical resistance, and mechanical strength in the presence of steam compared to EPDM.

Specification

If EPDM must be used in a steam application due to specific design constraints or material compatibility requirements with other process fluids, it is essential to consider the following:

- Temperature and Pressure Limits: Carefully evaluate the operating temperature and pressure of the steam system. If they exceed the recommended limits for EPDM in steam, consider alternative materials.

- EPDM Grade: Some specialized grades of EPDM may offer improved resistance to steam compared to standard grades. Consult with gasket manufacturers to identify suitable options, although even these specialized grades may have limited service life in severe steam conditions.

- Gasket Design: Optimize the gasket design and flange mating surfaces to minimize stress on the gasket and improve sealing performance.

- Regular Monitoring: Implement a rigorous monitoring program to detect any signs of gasket degradation or leakage. Regular inspections and preventative maintenance are crucial in steam applications where EPDM is used.

- Replacement Frequency: Be prepared for a significantly reduced service life of EPDM gaskets in steam compared to their performance in non-steam applications. Plan for more frequent replacements to prevent unexpected failures.

Conculustion

In conclusion, while EPDM gaskets offer excellent performance in many applications, they are generally not the optimal choice for high-temperature steam service. The aggressive nature of steam can lead to rapid degradation and premature failure. For reliable and safe operation in steam systems, it is highly recommended to select gasket materials specifically designed for such demanding conditions, such as expanded graphite, PTFE, or suitable CNAF materials. If EPDM is used, it should be done with a clear understanding of its limitations and with appropriate considerations for temperature, pressure, and regular monitoring.