Custom gaskets

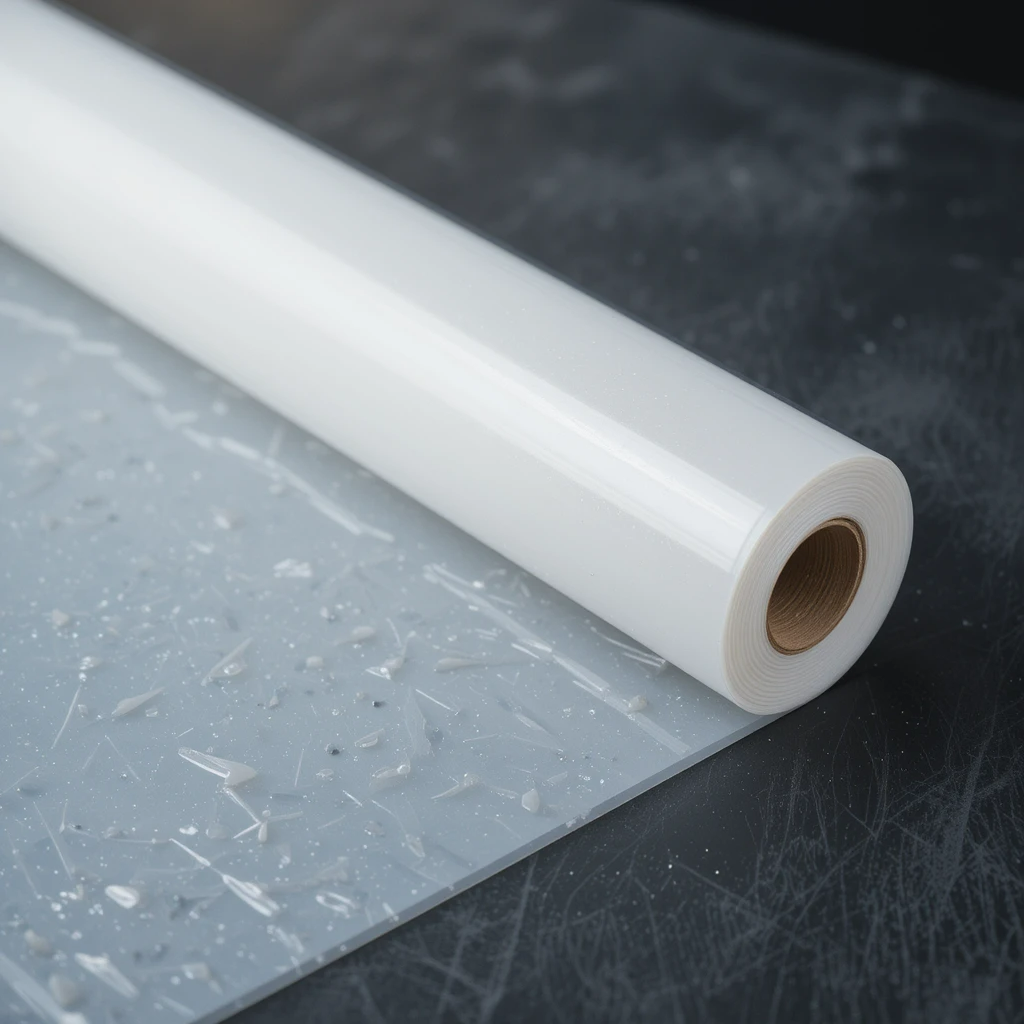

Silicone gasket sheet

Silicone gasket sheets represent a highly versatile and performant material specifically engineered for sealing applications across a multitude of industries. Composed of silicone rubber, these sheets are manufactured through processes that cure the polymer into a solid or sponge form, varying in thickness and durometer (hardness) to suit diverse operational requirements. Their utility as a gasketing material stems from a unique combination of physical and chemical properties that are often superior to organic rubbers and plastics in demanding environments.

Silicone specification

Primary among silicone’s advantageous characteristics is its exceptional temperature resistance. Silicone gasket sheets can maintain their sealing integrity and physical properties over an extremely wide temperature range, typically from -60°C to +230°C (-76°F to +450°F), with specialized formulations capable of enduring even higher or lower extremes. This makes them indispensable in applications exposed to significant thermal fluctuations, whether in high-temperature machinery or cryogenic equipment.

Silicone resistance

Beyond thermal stability, silicone exhibits remarkable resistance to weathering, ozone, and UV radiation. This inherent environmental durability ensures that gaskets fabricated from silicone sheets do not degrade or become brittle when exposed to outdoor conditions or prolonged sunlight, contributing to extended service life and reduced maintenance requirements compared to materials prone to environmental aging.

Silicone chemical resistance

Chemical inertness is another critical attribute. Silicone rubber is largely unaffected by many chemicals, oils, and solvents, though its resistance varies depending on the specific compound and the chemical involved. This property is particularly valuable in applications where sealing components come into contact with process fluids, lubricants, or cleaning agents, preventing degradation that could lead to leaks.

Silicone mechanical properties

Furthermore, silicone offers excellent flexibility and compression set resistance. It can conform effectively to irregular surfaces, creating a reliable seal even under low clamping forces. Its ability to recover its original shape after compression ensures long-term sealing performance, even in dynamic applications or those involving repeated cycles of pressure or temperature changes.

Electrical properties

The material’s electrical properties are also noteworthy. Silicone is an excellent electrical insulator, making silicone gasket sheets suitable for sealing enclosures in electronic equipment or other applications requiring dielectric strength.

Gasket application

Given these properties, silicone gasket sheets find widespread application. In the automotive sector, they are used for sealing engine components, lighting enclosures, and HVAC systems. The aerospace industry utilizes them for cabin sealing, engine gaskets, and electrical insulation due to their performance under extreme temperatures and pressures. The food and beverage industry relies on FDA-approved grades for sealing processing equipment, pumps, and valves, benefiting from silicone’s non-toxicity and resistance to high-temperature cleaning procedures. Similarly, the medical industry employs biocompatible silicone sheets for seals in devices, equipment, and prosthetic components. Industrial machinery, HVAC systems, and electrical enclosures also frequently incorporate silicone gaskets for reliable sealing against dust, moisture, and chemicals.

Parameters to consider

When selecting a silicone gasket sheet, critical parameters include the required temperature range, chemical compatibility with the media being sealed, mechanical requirements (such as pressure and compression), durometer (hardness), thickness, and compliance with relevant industry standards (e.g., FDA, USP Class VI, UL). Proper selection ensures optimal sealing performance and longevity in the intended application.

Conclusion

In conclusion, the silicone gasket sheet stands as a sophisticated and highly effective sealing material. Its combination of thermal stability, environmental resistance, chemical inertness, flexibility, and electrical insulating properties renders it an invaluable component in ensuring reliable sealing integrity across a broad spectrum of demanding industrial, commercial, and specialized applications.